DC COIL FORMING MACHINES

Semi-manual equipment to form DC coils.

These manual DC coil-forming machines are mainly divided into two complementary types:

- 180° bending and pre-forming bench for copper flat wires;

- Bench for final forming of DC coils.

- Easy of use and quick machine setting.

- Speeding up forming operations.

- Qualitative and repeatable forming results.

- Robustness and ergonomics.

- Full compliance with Industry 4.0 requirements.

Advantages:

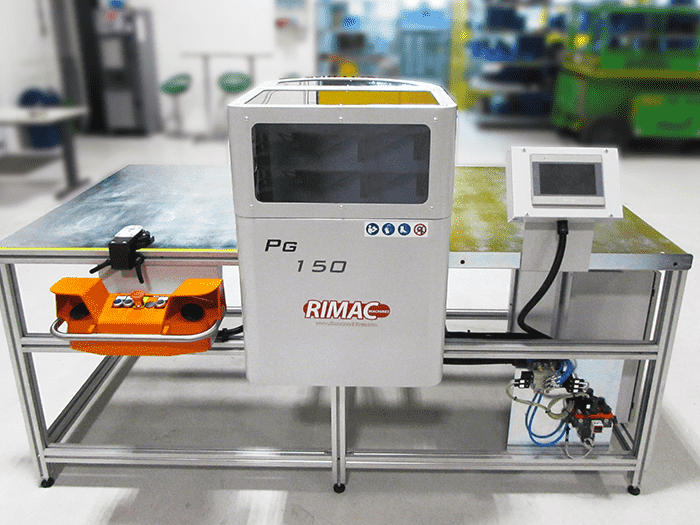

Flat wire bending bench

Technical features:

- Equipment specifically designed for 180° bending and 180° pre-forming of copper flat wires.

- 180° bending angle (+0…+3° for copper elasticity compensation).

- Electrically driven rotating bending arm for a total control of the bending phase.

- Pneumatic flat wire clamping.

- Possibility of bending several copper flat wires simultaneously.

- Touch screen control panel to easily select and set the type of bending and working speed, save work programs and exchange production data with the management system.

- Double push-button safety operation.

- Integrated Remote Assistance module: Rimac technicians can remotely connect to the machine and start a real-time remote assistance session. By accessing to the control panel and to the PLC and then checking the operation of the machine, our technician can intervene directly and solve the problem or provide timely guidance. The module can be connected via Ethernet connection, Wi-Fi or GSM card.

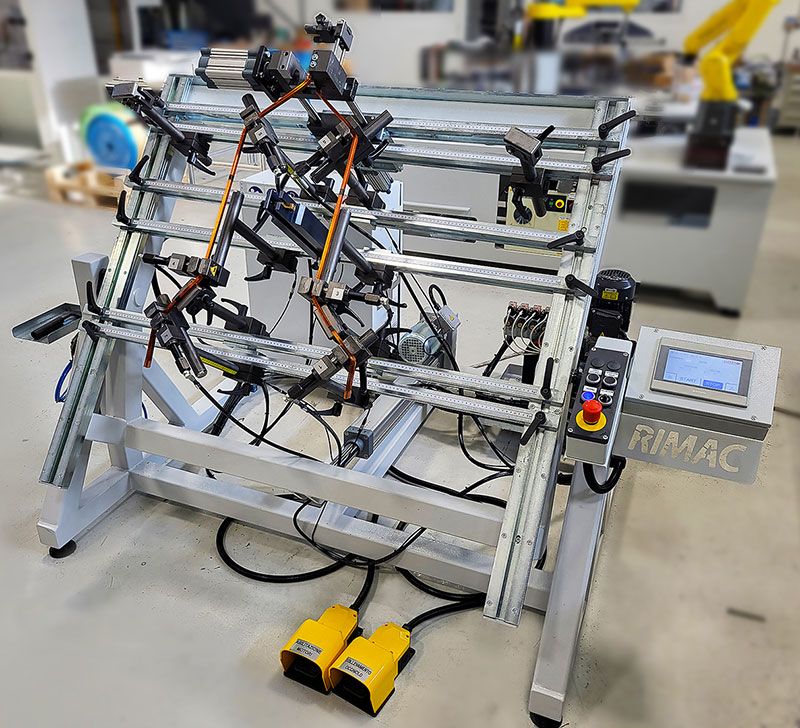

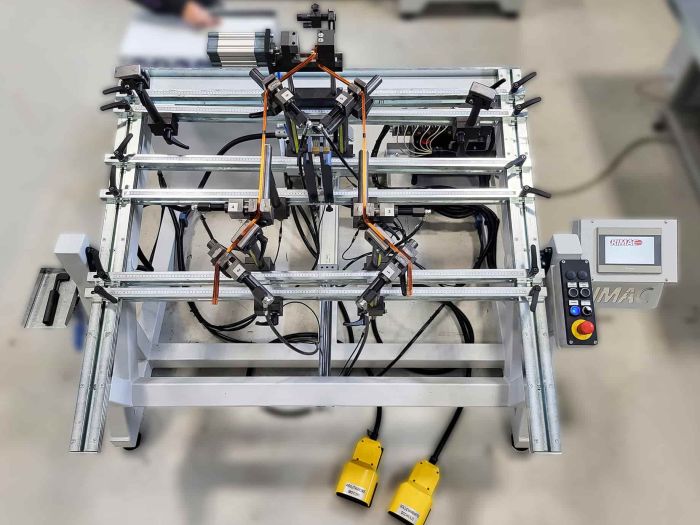

DC COIL FORMING BENCH

Technical features:

- Semi-manual machine designed to form DC coils with ‘frog leg’ or ‘diamond’ shape.

- Robust construction with electrically adjustable inclined work table for a better ergonomics during forming operations.

- Pneumatic coil knuckle clamp and six conductor clamps at the end of the slot parts.

- Each gripper is equipped with interchangeable tools to obtain optimal bending radii at the exit of the straight sections and on the knuckle.

- The machine can be equipped with a hydraulic system for the actuation of the clamps, whereby each clamp is automatically opened/closed by means of a dedicated button.

- Machine setting is at operator charge, and it is facilitated by visual references and metric lines present for each adjustment.

- The machine can be equipped with a PLC and HMI to save work programs and to exchange production data with the management system.

- Integrated Remote Assistance module: Rimac technicians can remotely connect to the machine and start a real-time remote assistance session. By accessing to the control panel and to the PLC and then checking the operation of the machine, our technician can intervene directly and solve the problem or provide timely guidance. The module can be connected via Ethernet connection, Wi-Fi or GSM card.

Via Doberdò 39 – 21046 Malnate (VA) – Italy | Ph: +39 0332 429963 | Fax: +39 0332 424639 | Email: info@rimacmachines.com

© 2023 Rimac Machines – Rimac S.r.l. – VAT nr. IT02569340132