BANDING MACHINES FOR DC MOTOR ROTORS

Automatic rotor banding machines, whose primary function is to apply banding tape to DC motor armatures in a controlled and parameterizable manner. Rimac range of banding machines is extensive and includes various models that can be chosen based on the dimensions of the armature to be banded and the required level of automation. Rimac is the international market reference for rotor banding machines.

- Optimal and repeatable banding results thanks to automatic tape tension control and precise overlap management.

- Possibility to integrate pre-heating systems for more effective application.

- Possibility to work in manual, semi-automatic, or automatic mode.

- Complete monitoring of the banding process and results.

- Possibility to store a work program for each rotor reference.

- Possible combination with other functions (brushing, undercutting, welding, turning and coil leads cutting).

- Full compliance with Industry 4.0 requirements.

Advantages

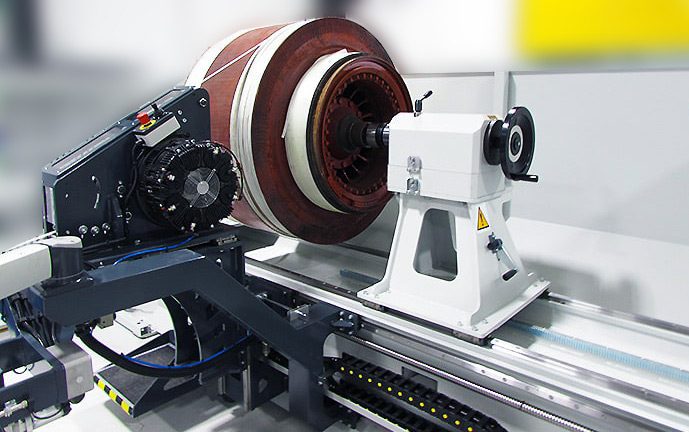

AUTOMATIC BANDING MACHINES

Technical features:

- Load cell for display and automatic control of tape tension, with closed-loop control and adjustment system.

- Maximum tape tension achievable and continuously maintainable: 3500 N.

- Electrical drives for the translation of the banding carriage and the rotation of the armature ensure maximum control of the banding pitch, allowing precise overlap management.

- Dedicated heating system to heat the tape application area to the desired temperature, making the application more effective. This solution enables higher performance of pre-impregnated tapes.

- Possibility to use pre-preg tapes of any type, such as Isoglas, Polyglas, and other brands.

- Possible execution of the banding cycle in manual, semi-automatic, or automatic mode.

- Operator platform with operator presence sensors that allow the operator to work close to the rotor to apply other materials and monitor the process.

- Possibility to set and store a work program for each specific rotor reference.

- Possible installation of the banding unit in multi-function machines that combine multiple work functions (brushing, undercutting, welding, turning and coil leads cutting).

- Integrated remote assistance module: Rimac technicians can remotely connect to the machine and initiate real-time remote assistance sessions. By accessing the control panel and the PLC and thus verifying the machine’s operation, Rimac’s technician can intervene directly to resolve issues or provide timely guidance. The module can be connected via Ethernet, Wi-Fi, or GSM card.

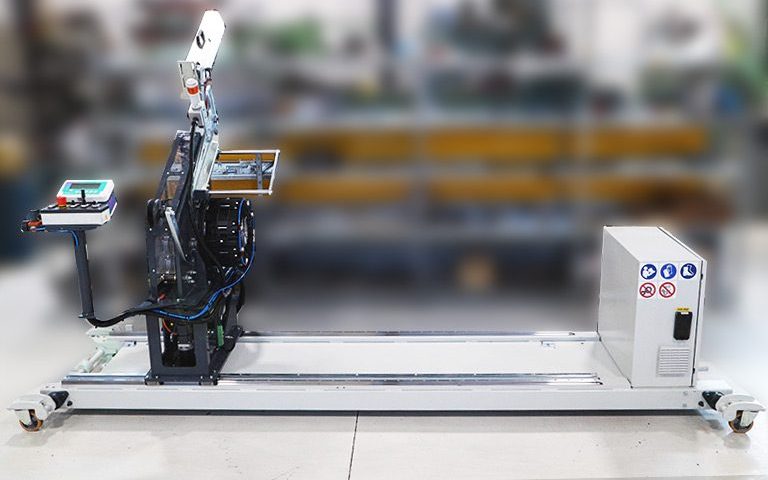

BANDING UNIT

Technical features:

- Stand-alone units to interface with an existing rotor support and rotation system (e.g., lathe type).

- Load cell for automatic tape tension control, with closed-loop control and adjustment system.

- Analog indicator for monitoring the tension applied to the tape.

- Motorized and adjustable-speed translation of the banding unit on the frame.

- Frame to be fixed on the floor or equipped with wheels to be movable.

- Dedicated heating system to heat the tape application area to the desired temperature, making the application more effective.

- Integrated remote assistance module: Rimac technicians can remotely connect to the machine and initiate real-time remote assistance sessions. By accessing the control panel and the PLC and thus verifying the machine’s operation, Rimac’s technician can intervene directly to resolve issues or provide timely guidance. The module can be connected via Ethernet, Wi-Fi, or GSM card.

Via Doberdò 39 – 21046 Malnate (VA) – Italy | Ph: +39 0332 429963 | Fax: +39 0332 424639 | Email: info@rimacmachines.com

© 2023 Rimac Machines – Rimac S.r.l. – VAT nr. IT02569340132