BANDING LAB

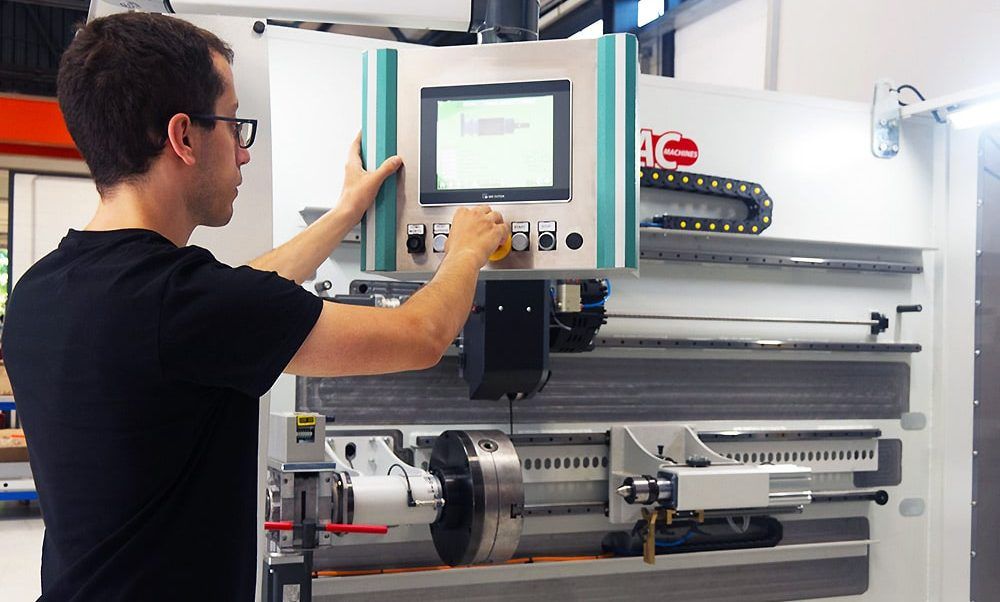

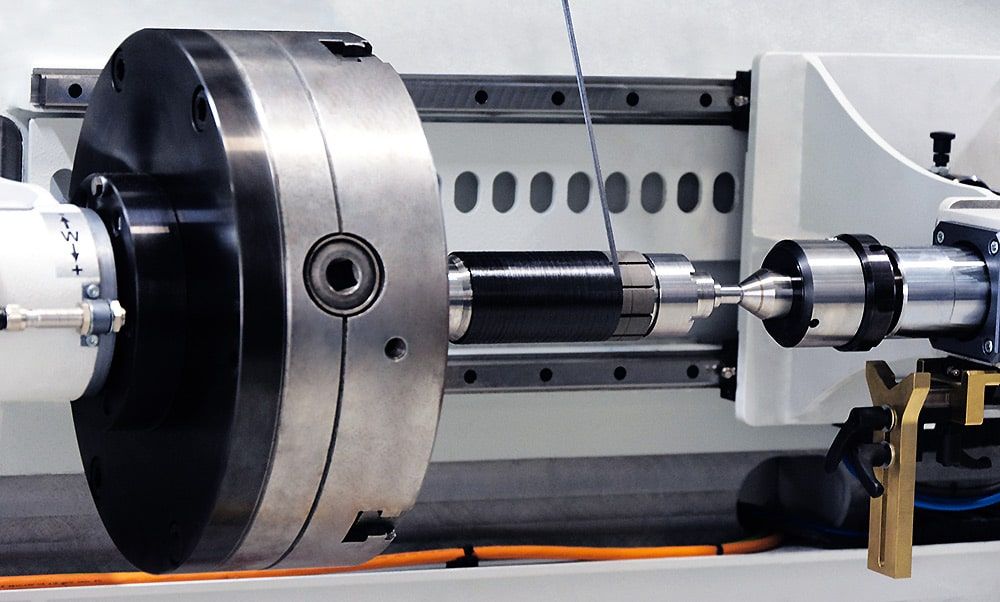

Il Banding Lab Rimac è un centro di tecnologia applicata ben attrezzato, che dispone di macchinari di bandatura rotore avanzati e versatili, che vengono utilizzati per eseguire prove di bandatura su rotori aventi varie configurazioni e dimensioni.

- Possibilità di usufruire del know-how e dell’esperienza di Rimac in questo ambito per definire il migliore processo di bandatura per ogni specifico modello di rotore.

- Servizio di dimensionamento completo tramite modello di calcolo matematico per definire il precarico necessario per ogni specifico rotore nel suo campo di applicazione.

- Supporto e collaborazione con il team Rimac per l’identificazione e la scelta del materiale migliore per ogni applicazione e relativo fornitore.

- Supporto di personale altamente qualificato e con un elevato know-how specifico di processo.

- Possibilità di assistere ai test in presenza tramite apposito pacchetto commerciale.

- Possibilità di ricevere campioni di rotori bandati secondo specifica per test di tenuta e spinning test.

- Possibilità di testare varie tipologie di nastri e resine per resistenze anche ad altissime temperature (> 200°C).

- Possibilità di fornire attività di produzione conto terzi per lotti fino ad un massimo di circa 5.000 pezzi/anno.

Vantaggi:

Banding Lab

Le attività del Banding Lab includono:

- Analisi preliminare del design rotore.

- Selezione e acquisto del materiale di bandatura (nastri pre-impregnati in fibra di vetro/ nastri pre-impregnati in fibra di carbonio).

- Prove di bandatura.

- Produzione di campioni.

- Analisi dei risultati e redazione di report.

Servizi di bandatura

Rimac è anche in grado di offrire i seguenti servizi di bandatura per rotori a magneti permanenti: realizzazione di prototipi e produzione di piccole serie. Le attività inerenti ai servizi di bandatura includono:

- Bandatura di prototipi o piccole serie, utilizzando i componenti e il materiale di bandatura del cliente (nastri pre-impregnati in fibra di vetro/ nastri pre-impregnati in fibra di carbonio)

- Controllo qualità sui rotori bandati

- Analisi dei risultati e redazione di report

Rimac è il punto di riferimento del mercato internazionale per le macchine di bandatura rotori a magneti permanenti.

© 2023 Rimac Machines – Rimac S.r.l. – P.IVA 02569340132